MPA has placed environmental responsibility at the heart of our operations since 1968.

Our remanufacturing process isn’t just efficient; it’s a game-changer for sustainability in the automotive industry.

With the potential to cut material and energy consumption by up to 85%, remanufacturing is the most efficient and sustainable process for producing aftermarket replacement parts, making MPA’s business practices green by nature.

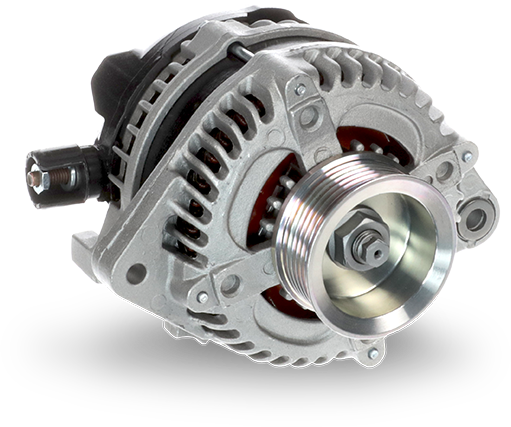

MPA’s longstanding commitment to sustainability dates back to our founding in 1968. Environmentally sustainable processes were at the core of our business practices then, just as they are now. Not only does MPA’s comprehensive clean-tech remanufacturing process produce starters, alternators, and other components that deliver superior performance and reliability, it also makes a significant positive impact in terms of sustainability.

By renewing and reconditioning components, MPA saves energy and materials while delivering dependable, like-new performance.

By renewing and reconditioning components, MPA saves energy and materials while delivering dependable, like-new performance.

Renewing is a process that restores previously manufactured parts to like-new condition instead of producing entirely new ones. This approach preserves the energy already invested in a product and, compared to traditional manufacturing, requires only a fraction of the additional resources.

Producing a new starter, for example, requires more than ten times the energy and nine times the raw materials needed to produce a renewed one. Similarly, a new alternator consumes about seven times the energy and eight times the raw materials compared to a renewed unit. Studies estimate that renewing a starter or alternator saves up to 85% of the energy otherwise required to manufacture a new part.

These energy savings directly translate into lower carbon emissions and reduced resource consumption. In fact, renewed products are estimated to conserve the equivalent of 400 trillion BTUs of energy per year. By focusing on renewal, MPA takes measurable steps to reduce greenhouse gas emissions and mitigate the impacts of climate change.

Sustainability isn’t just a practice at MPA—it’s our legacy. Since 1968, we’ve pioneered remanufacturing to give automotive parts a second life, cutting material and energy use by up to 85% compared to new production. It’s not just efficient—it’s transformative.